NOAA Smart Balloon

INTRODUCTION

The FRD designs and deploys a smart balloon that is suitable for hurricane research and other atmospheric measurement

tasks. Other participants in this project include the the U.S. Weather Research Program (USWRP), NOAA Air Resources

Laboratory, Field Research Division, and the University of Hawaii.

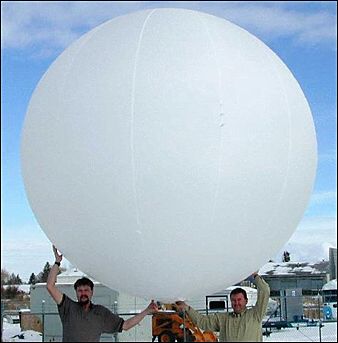

The smart balloon is constant volume, variable density, 10.3-foot diameter balloon. The shell

is designed to house the transponder and sensors inside the balloon shell to help protect them from turbulence, rain,

and impacts. It has temperature and relative humidity sensors housed in a

radiation shield and fan aspirated to increase accuracy. A rain gage provides information on the

precipitation rate as the smart balloon moves through rain bands within a hurricane. An infrared temperature sensor

provides remote sea-surface temperature data. Satellite communications allow continuous monitoring of the balloon

position and sensor data without requiring an aircraft to be in close proximity to the smart balloon.

The smart balloon is deployed as a part of a Lagrangian experimental strategy to better characterize the evolution of

the energy content of the marine boundary-layer inflow to a hurricane and its relationship with hurricane intensity

changes. This effort is accompanied by reconnaissance missions flown by the NOAA Hurricane Research Division.

|  |

Smart balloon with the transponder packaged inside the balloon shell rather than tethered under the balloon.

This protects the transponder from rain impact damage. The smart balloon is tough enough to be launched

into hurricanes.

|

|

BALLOON DESIGN

The constant volume balloon shell is made from a high-strength fabric that allows the balloon to be pressurized without

tearing the balloon and with minimal increase in the balloon volume. A high-strength fabric is necessary for the

following reasons: 1. When pressurized to the maximum operating pressure, over 50,000 pounds of force are exerted on

the balloon shell. 2. Any elasticity in the fabric requires additional pumping time and energy to adjust the balloon

altitude.

Transponder Protection

The smart balloon carries the transponder

inside an airtight tube within the balloon shell, protecting the transponder from rain and impact with solid objects.

This arrangement also lets the enclosure tube interface with the internal bladders and balloon shell, and it saves

on weight and space relative to housing the transponder beneath the balloon.

The drawing to the right shows the integration of the helium fill tube and air ballast tube into the transponder

enclosure tube. The air ballast tube is connected to a pump and release valve inside the transponder. These pump air

into or release air from the ballast portion of the balloon, thereby controlling the balloon's elevation.

The helium tube is used only when the balloon is initially filled and is then sealed.

A cut down device installed on the top of the balloon releases helium.

|  |

Cross section of balloon and its primary features.

|

|

Rain Repellent Shell for Balloon

The balloon shell must be constructed of a very tough and lightweight material that protects the balloon's air and

helium bladders and does not stretch. The selected material is a porous fabric that slows, but does not stop, the

migration of air or water between the exterior and interior of the balloon shell. Consequently, the shell will

absorb water when rain is encountered, increasing the balloons weight. To reduce rain absorption and help ensure

that the balloon can remain aloft when wet, a plastic cover or skirt covers the upper half of the balloon.

A future goal is to develop a lightweight shell that completely repells water. This will eliminate the need for

the plastic cover and let the balloon carry additional weight even when wet.

|  |

Spectra balloon shell that has been sprayed with water. Note that the combination of the tight

fabric weave and the water repellent treatment causes the water to bead up and roll off the balloon

rather than soak into the fabric.

|

|

Air and Helium Bladders

Early balloon designs used large weather balloons (300 and 600 grams) inside the high strength shell to contain

the helium and air ballast. Althought this was a simple and low cost method, the balloons tended to lose helium, and

they showed unacceptable wear from chaffing against the shell seams.

The current design uses polyurethane bladders because they offer very low permeability to helium without any special

polymer treatment, they have the required flexibility and elasticity, and they do not exhibit chaffing-induced wear.

|  |

High strength yet elastic 1 mil polyurethane film is used to make bladders for the smart balloon.

|

|

INSTRUMENTATION

Packaged instruments that fit inside the 6-inch transponder tube within the balloon.

|

The purpose of the smart balloon is to obtain measurements as it moves through a hurricane or carries out other

assignments.

Infrared Thermometer

Measuring the sea surface temperature is critical in estimating the sea surface heat fluxes. Since the balloon is several hundred meters above the sea surface, it is necessary that this measurement be made remotely.

An Apogee infrared temperature sensor has been added to the smart balloon to estimate sea- surface temperature based on the emitted infrared radiation. Unlike conventional thermometers, the infrared thermometers do not need to come in direct contact with the object or surface temperature being measured. The Apogee infrared sensor is mounted at the bottom of the transponder enclosure tube with an opening in the horizontal plate to allow a downward view of the sea surface. Accuracy of this thermometer is one degree centigrade and has a resolution of .1 degree centigrade. Because the sensor measures the temperature within the field of view, it will measure the temperature of any other objects that emit infrared radiation between the sensor and the sea surface (such as rain and sea spray).

|

Apogee IR temperature sensor.

|

Solar Radiation

Solar radiation is sensed with a precision Licor LI200X. This pyranometer measures incoming

solar radiation with a

silicon photovoltaic detector mounted in a cosine-corrected head.

This pyranometer is calibrated against an Eppley

Precision Spectral Pyranometer to accurately measure sun plus sky radiation to within 2% over a broad temperature range.

This sensor weighs only one ounce and is less than one inch in diameter. This small size allows the sensor to be easily

mounted on the balloon top-plate.

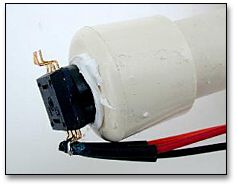

Rain Gage

Because the smart balloon's weight is affected by rain, a miniature precipitation gage is mounted on the top

plate of the smart balloon. This helps improve general understanding of the balloon's behavior and helps in predicting

the necessary altitude control actions that need to be initiated.

The miniature rain gage is built into the top plate of the balloon allowing the gage to measure up to 15 inches of

precipitation before it is full. A small pressure transducer in the base of the rain gage converts the water column

pressure to total rain. Because vertical balloon motion shows up as changes in the water column pressure the data

is processed through a low pass filter to remove high frequency noise caused by turbulence and motion.

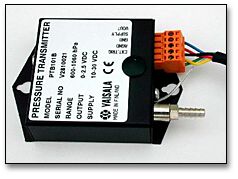

Barometric pressure transmitter

|

Barometric Pressure, Temperature, and Relative Humidity

A Vaisala model PTB101B pressure transmitter was selected for accuracy, small

size and low power requirements. The pressure range of this sensor is 600 to

1060 millibars. Total accuracy is �2 millibars, with a linearity of �.45

millibars and a hysteresis and repeatability of �.05 millibars. This pressure

sensor uses only 4 milliamps when active and can be turned off between

measurements. Temperature dependence of the output is rated at �.05 millibars

per degree centigrade. Altitude accuracy is improved by processing the GPS

altitude data and barometric pressure altitude data through a low pass filter to

provide a correction to the real-time barometric pressure altitude.

Temperature and humidity measurements use an aspirated temperature shield inside the transponder

and a high quality Vaisala HMP45C temperature and relative humidity probe. The radiation shield is made of thin wall

copper tubing and aluminum with an aspirator fan pulling 250,000 cubic centimeters per minute past the probe

continuously. The air is isolated from other instruments inside the transponder to protect them from condensing

moisture and possible sea salt.

Temperature accuracy for the probe is within �.4 degrees centigrade and a resolution and repeatability of �.05 degrees

centigrade.

Relative humidity accuracy is within �3% over the full range of 0 to 100% relative himidity. Resolution and

repeatability of the relative humidity are �.05%. The long term stability of the relative humidity portion of this

probe is better than �1% per year.

|  |

Licor LI200X solar radiation sensor.

Rain gage sensor (pressure transducer measuring water column height).

Temperature and relative humidity probe.

|

|

BALLOON ALTITUDE CONTROL

The smart balloon is controlled by pumping air into (decreased the balloon altitude) or releasing air from (increased the balloon altitude) the pressurized air ballast portion of the balloon. Each liter of air stored in the ballast portion of the balloon weighs about 1.2 grams per liter at sea level. Since the balloon volume is constant under pressure, the density of the balloon changes when ballast air is increased or decreased.

Control of pumping and release valve action is determined by comparing the actual flying altitude to the desired altitude setting. The actual altitude is updated every second by the onboard GPS receiver. Prior to launch or even during flight the desired altitude range is controlled by the operator on the ground. The smart balloon micro controller maintains this data and manages control of the pump and release valve operations for total autonomous operation. The operator is able to override automatic altitude control with manual operation of the release valve or turning the pump on/off.

Ballast release pinch valve.

|

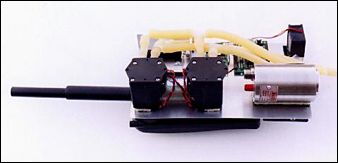

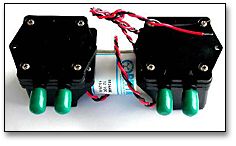

Dual Head Pump

Pumping rate has been doubled by using a dual head pump. The new pump is capable of pumping 26.4 grams (22 liters) of air per minute at a balloon pressure of 1.5 psi. See table 3 for more complete information on the pumping rate.

Ballast Release Valve

An electro-mechanical pinch valve was specifically designed by FRD to allow faster ballast release rate. The new pinch valve uses a small, low power gear head motor and pinch plate to make a very high flow rate (when open) valve. Advantages to this type of valve include:

- Low power operation and no power required once it is open or closed.

- Once the tube is pinched closed pressure from the tubing actually keep the pinch valve latched closed.

- Much larger diameter tubing can be used which allows for faster release of ballast air.

|  |

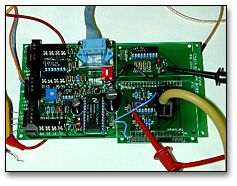

The transponder interface is the control center of the hurricane balloon. The micro controller

mounted on the back side of this printed circuit board provides all measurement and control

functions for the balloon. The low power GPS receiver is also mounted on the back side of this

circuit board.

Dual head pump.

|

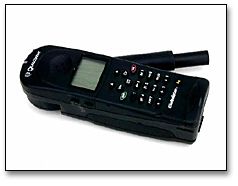

SATELLITE COMMUNICATIONS

With the very recent introduction of a small satellite telephone on the market, it is now feasible to use one of these for data communications on the smart balloon. A handheld Globalstar satellite telephone has been selected for this purpose. Some of the advantages of using the new satellite phones are:

- A data gathering aircraft is not required to relay data from the balloon to the ground over the period of tracking (12 to 24 hours).

- Data receiving equipment is required in only one location rather than on the ground and multiple aircraft.

- Tracking is simplified by keeping tracking and control in one location (preferably at the release site where balloon control will take place). Balloon data will be forwarded to other scientists at the experiment operations center and on participating aircraft via the Internet.

- The Satellite telephones are a several hundred dollars less expensive than the VHF radio/modem combination that were used during ACE-2.

- Even though talk time is expensive ($1 to $1.50 per minute), additional equipment and aircraft time make the alternative much more expensive and less flexible.

- A data rate of 9600 bits per second provide data at about 8 times the rate available previously over long distances (50 to 200 miles). This increased data bandwidth allows for one second update of position and meteorological data and still allows for retransmission of data that may be found in error.

- No modem is required. The satellite phone is digital and only an RS-232 adapter cable is required.

|  |

Globalstar satellite telephone.

|

SUMMARY

The new generation of smart balloons serve as a data gathering platform that can withstand a hurricane environment.

A number of recent technical advances make this possible, including the appearance of lightweight, affordable satellite

telephones, improvements in balloon and transponder design, better instrument accuracy, and improved GPS position and

altitude accuracy.

|  |

|

|